Efficient medical device manufacturing is the key to delivering high-quality, compliant, and cost-effective products to market. As the demand for innovative medical devices continues to grow, manufacturers face increasing pressure to streamline processes while meeting stringent regulatory requirements. This comprehensive guide provides actionable strategies to optimize medical device manufacturing and gain a competitive edge in the market.

Table of Contents

What Is Medical Device Manufacturing?

Medical device manufacturing encompasses the processes of designing, producing, and delivering devices intended for medical use. It involves a wide range of activities, including prototyping, validation, scaling, and post-market surveillance. A successful medical device manufacturing process ensures that devices meet regulatory standards, maintain high quality, and are produced cost-effectively.

1. Integrate Design for Manufacturability (DFM)

Design for Manufacturability (DFM) is the foundation of efficient medical device manufacturing. It involves designing medical devices with production scalability and efficiency in mind.

Key Principles of DFM

- Simplification: Reduce the number of components to minimize assembly time.

- Standardization: Use off-the-shelf parts wherever possible to cut costs.

- Material Selection: Choose materials that are readily available and easy to process.

Action Steps

- Conduct DFM reviews at every design milestone.

- Use simulation tools to identify and resolve potential production bottlenecks.

- Collaborate with manufacturing engineers early in the design phase.

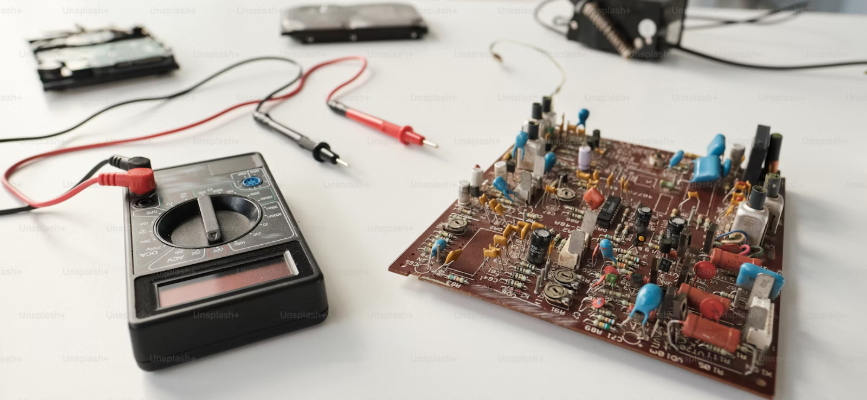

2. Leverage Automation and Technology

Automation can significantly enhance precision, consistency, and throughput in medical device manufacturing.

Areas for Automation

- Assembly: Automate repetitive tasks such as component assembly and welding.

- Inspection: Use machine vision systems for quality control.

- Packaging: Implement robotic systems for packaging to improve efficiency.

Emerging Technologies

- IoT (Internet of Things): Real-time monitoring of production lines to minimize downtime.

- AI and Machine Learning: Predict equipment maintenance needs and optimize workflows.

- 3D Printing: Rapid prototyping and production of complex components.

3. Implement a Robust Quality Management System (QMS)

A strong QMS ensures consistent product quality and compliance with regulations such as ISO 13485 and FDA requirements.

Key Elements of QMS

- Document control for traceability.

- Regular internal and external audits.

- Continuous monitoring of key performance indicators (KPIs).

Best Practices

- Use QMS software to digitize and centralize compliance documentation.

- Train all employees on quality standards and regulatory updates.

- Conduct root cause analysis for any quality issues to prevent recurrence.

4. Optimize Supply Chain Management

Efficient supply chain management reduces lead times, minimizes costs, and ensures uninterrupted production.

Strategies

- Multi-Sourcing: Avoid dependency on single suppliers for critical components.

- Inventory Optimization: Use just-in-time (JIT) strategies to reduce storage costs.

- Supplier Collaboration: Work closely with suppliers to ensure material quality and timely delivery.

Risk Mitigation

- Maintain safety stock for high-risk components.

- Regularly audit suppliers to ensure compliance with your quality standards.

5. Validate Manufacturing Processes

Process validation is critical to ensure that manufacturing consistently produces devices meeting design specifications.

Steps in Process Validation

Process validation is essential for ensuring that manufacturing processes consistently produce medical devices meeting predefined specifications and quality standards. The validation process typically involves three critical steps: Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ). Each step builds on the previous one to ensure the equipment and processes are robust, repeatable, and compliant with regulatory requirements.

1. Installation Qualification (IQ): Ensuring Proper Installation

Purpose: The IQ step ensures that all equipment, utilities, and systems are installed correctly according to manufacturer specifications and meet regulatory and operational requirements.

Steps in IQ:

- Equipment Verification: Confirm that all components and equipment match the specified design and purchase orders.

- Utility Connections: Verify that utilities such as electricity, water, and compressed air are properly connected and functional.

- Documentation Check: Ensure manuals, certifications, and calibration records are available and up to date.

- Environmental Controls: Verify environmental conditions, such as humidity and temperature, meet the specified ranges for operation.

Key Deliverables:

- Installation checklist.

- Equipment calibration certificates.

- IQ validation report.

2. Operational Qualification (OQ): Validating Operating Conditions

Purpose: The OQ step tests the equipment and processes under the defined operating conditions to ensure they function as intended.

Steps in OQ:

- Define Parameters: Identify critical process parameters (e.g., temperature, speed, pressure) that need validation.

- Execute Tests: Run tests across the operating range, including minimum and maximum limits.

- Safety Testing: Validate safety features, including alarms and interlocks, to ensure they operate correctly.

- Simulate Variations: Introduce expected variations in materials, inputs, and environmental conditions to test equipment resilience.

Key Deliverables:

- Test protocols and results.

- Documentation of any deviations and resolutions.

- OQ validation report.

3. Performance Qualification (PQ): Confirming Consistent Output

Purpose: The PQ step demonstrates that the equipment and processes consistently produce the desired outcomes during actual production runs.

Steps in PQ:

- Simulate Full Production: Run multiple production cycles using actual materials and operators to simulate real-world conditions.

- Monitor Outputs: Verify that the product meets all quality specifications and standards.

- Identify Variations: Test the process’s ability to handle variations without compromising quality.

- Document Findings: Capture detailed records of performance, including any adjustments or observations.

Key Deliverables:

- Process capability study.

- Production test results.

- PQ validation report.

Best Practices for Successful Process Validation

- Develop a Validation Master Plan (VMP): Create a comprehensive plan outlining all validation activities, roles, responsibilities, and timelines.

- Use Cross-Functional Teams: Include experts from quality, engineering, and production teams to ensure all aspects are covered.

- Document Everything: Maintain meticulous records at every step to ensure traceability and compliance during audits.

- Automate Data Collection: Leverage digital tools to capture and analyze validation data in real-time.

- Iterate and Refine: Address any deviations immediately and update protocols to prevent future issues.

Tips for Effective Validation

- Develop detailed validation protocols.

- Use pilot runs to test processes before full-scale production.

- Document all validation activities for regulatory compliance.

6. Streamline Regulatory Compliance

Compliance is non-negotiable in medical device manufacturing. Regulatory bodies such as the FDA and EU MDR impose strict requirements to ensure safety and efficacy.

Steps to Streamline Compliance

- Align your processes with standards such as ISO 13485 and ISO 14971 (risk management).

- Use digital tools like Greenlight Guru to manage compliance documentation for medical device manufacturing.

- Schedule regular audits and reviews to identify and resolve gaps early.

7. Focus on Workforce Training

A skilled and knowledgeable workforce is essential for optimized medical device manufacturing processes.

Training Programs

- Provide hands-on training for operating complex machinery.

- Offer regular updates on new regulations and quality standards.

- Emphasize the importance of quality control and risk management.

Retention Strategies

- Foster a culture of continuous learning.

- Provide incentives for employees who obtain certifications in relevant areas.

8. Use Data Analytics for Continuous Improvement

Data-driven decision-making can uncover inefficiencies and opportunities for optimization in manufacturing processes.

Key Metrics to Monitor

- Yield rates and defect percentages.

- Equipment downtime and maintenance frequency.

- Production cycle times.

Tools

- Implement ERP (Enterprise Resource Planning) systems for real-time data tracking.

- Use predictive analytics to anticipate demand and optimize production schedules in medical device manufacturing.

9. Incorporate Lean Manufacturing Principles

Lean medical device manufacturing eliminates waste, reduces costs, and enhances productivity.

Core Principles

- Value Stream Mapping: Identify and eliminate non-value-adding steps.

Value Stream Mapping (VSM) is a pivotal Lean management tool that enables organizations to visualize and analyze the flow of materials and information required to deliver a product or service to the customer. By mapping out each step in a process, VSM helps identify and eliminate non-value-adding activities—those that consume resources without enhancing the final product’s value.

Identifying Non-Value-Adding Steps:

Non-value-adding activities, often referred to as waste or “muda” in Lean terminology, include:

- Waiting Times: Delays where products or information await the next process step.

- Excessive Transportation: Unnecessary movement of materials or products between processes.

- Overproduction: Producing more than what is immediately needed, leading to excess inventory.

- Unnecessary Motion: Excessive movement by employees that does not add value.

- Defects and Rework: Errors requiring correction, leading to wasted time and resources.

By employing VSM, organizations can pinpoint these inefficiencies within both individual processes and the broader value stream, facilitating targeted improvements.

Eliminating Non-Value-Adding Steps:

Once identified, non-value-adding activities can be addressed through:

- Process Redesign: Streamlining workflows to remove unnecessary steps.

- Standardization: Implementing standardized procedures to ensure consistency and efficiency.

- Employee Training: Educating staff on Lean principles to foster a culture of continuous improvement.

- Technology Integration: Utilizing automation and information systems to reduce manual errors and delays.

For a deeper exploration of VSM in the medical device industry, consider reading Value Stream Mapping in the Medical Device Industry.

By effectively applying VSM, organizations can enhance operational efficiency, reduce costs, and deliver greater value to customers.

- Kaizen (Continuous Improvement): Encourage small, incremental improvements.

Kaizen, a Japanese term meaning “continuous improvement,” is a philosophy that emphasizes making small, incremental changes to processes, systems, and activities to enhance efficiency and quality. In the medical device manufacturing industry, implementing Kaizen principles can lead to significant improvements in productivity, quality, and regulatory compliance.

Key Aspects of Kaizen in Medical Device Manufacturing:

- Employee Involvement: Encouraging all employees, from management to the production floor, to actively participate in identifying areas for improvement fosters a culture of continuous enhancement.

- Waste Reduction: By systematically eliminating non-value-added activities, manufacturers can streamline operations and reduce costs.

- Standardization: Developing and adhering to standardized processes ensures consistency, which is crucial for maintaining quality and meeting regulatory standards.

- Problem-Solving: Utilizing structured problem-solving techniques enables teams to identify root causes of issues and implement effective solutions.

By embracing Kaizen, medical device manufacturers can achieve operational excellence, enhance product quality, and ensure compliance with stringent industry regulations.

- 5S Methodology: Organize workspaces for efficiency (Sort, Set in order, Shine, Standardize, Sustain).

Implementation

- Conduct regular workshops to identify areas of improvement.

- Reward teams for implementing successful process optimizations.

10. Plan for Scalability

As demand for your medical device grows, your manufacturing processes must be able to scale without compromising quality or efficiency.

Scalability Strategies

- Design flexible production lines that can accommodate changes in volume.

- Invest in modular equipment that can be expanded as needed.

- Build strong relationships with scalable suppliers.

Common Challenges in Medical Device Manufacturing

- Regulatory Complexity: Missteps in compliance can result in delays or recalls.

- Supply Chain Disruptions: Material shortages or delays can halt production.

- High Costs: Inefficient processes increase production costs and reduce margins.

- Maintaining Quality at Scale: Rapid growth can lead to inconsistencies in product quality.

Conclusion

Optimizing medical device manufacturing processes requires a blend of innovative technologies, efficient workflows, and rigorous quality controls. By integrating DFM principles, leveraging automation, streamlining compliance, and fostering a culture of continuous improvement, manufacturers can enhance productivity, reduce costs, and maintain the highest quality standards.

For a deeper dive into medical device engineering and its role in commercialization, check out this comprehensive guide on optical medical device development. It explores practical strategies to bring innovative devices to market effectively.

With the right strategies, you can navigate the complexities of medical device manufacturing and ensure your products are delivered to market efficiently and effectively.

Are you ready to optimize your medical device manufacturing processes? Let’s discuss how to implement these strategies for your business.

430 Park Ave, New York, NY 10022, USA

430 Park Ave, New York, NY 10022, USA Paevalille tn 6, Office 84, Estonia, Tallinn, 13517

Paevalille tn 6, Office 84, Estonia, Tallinn, 13517 Barykadna St 7, Dnipro, Ukraine, 49000

Barykadna St 7, Dnipro, Ukraine, 49000