As we move into 2025, the medical technology industry faces both challenges and exciting opportunities. One of the most significant trends shaping the future of medtech development is rapid prototyping. This process has been revolutionizing how companies bring medical devices from concept to reality—faster, cheaper, and with greater precision. Whether you’re a startup or an established medtech player, rapid prototyping is your ticket to staying ahead of the competition in the new year.

Table of Contents

In this article, we’ll explore how you can leverage rapid prototyping to kick-start your medtech innovation, expedite FDA approvals, and ensure your product is ready to meet market demands in 2025. Let’s dive into how this cutting-edge tool can help you make this year your most successful yet.

Introduction: The New Year, New Prototyping Opportunities

As we head into 2025, many medtech startups and innovators are evaluating their strategies for the year ahead. One thing is clear: the ability to quickly develop and test new products will be a key competitive advantage. Rapid prototyping is no longer just an optional step—it’s an essential tool for any medical device company looking to scale quickly and meet ever-increasing regulatory and market demands.

This New Year, let’s talk about how rapid prototyping can help you hit the ground running and achieve faster FDA approvals, reducing costs and development time, all while keeping your device compliant and market-ready.

What Is Rapid Prototyping and Why It’s a Game Changer for MedTech?

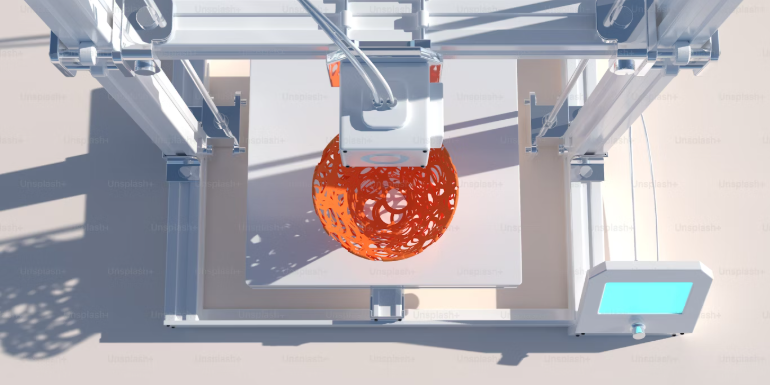

At its core, rapid prototyping is the process of quickly creating a prototype of a product using digital tools such as 3D printing, CNC machining, or laser cutting. In medtech, this means developing a physical model of your device that you can test, evaluate, and refine before mass production.

For medtech innovators, rapid prototyping offers several advantages:

- Faster iteration: You can test and refine your device quickly, reducing the risk of costly setbacks later in the process.

- Lower costs: Traditional prototyping methods can be expensive and time-consuming. With rapid prototyping, you can get a working model with fewer resources.

- Real-world testing: The faster you can create a prototype, the sooner you can test it in real-world conditions, giving you the insights needed for better design and performance.

How Rapid Prototyping Speeds Up FDA Approvals and Time to Market

One of the biggest barriers to bringing medical devices to market is securing FDA approval. The process can be long, expensive, and full of regulatory hurdles. However, rapid prototyping allows you to speed up the process in several key ways:

- Faster Design Iteration

By quickly creating prototypes, you can identify and address design flaws early in the process. This reduces the number of redesigns needed before submitting your device for FDA approval, ultimately cutting down the time it takes to bring your product to market. - Improved Testing and Validation

Testing prototypes early helps ensure that your device meets both functional and safety standards. With rapid prototyping, you can conduct usability testing, clinical evaluations, and preclinical trials to gather crucial data needed for FDA approval. - Clearer Regulatory Pathways

Having a tangible prototype makes it easier to work with the FDA and demonstrate that your product is ready for approval. With a well-tested prototype, you can clearly show the device’s capabilities and compliance, simplifying the regulatory process.

Busting Common Myths About Rapid Prototyping in MedTech

As with any cutting-edge technology, there are myths that surround rapid prototyping. Let’s bust a few of these misconceptions:

Myth #1: “It’s Only for Simple Products”

The Reality:

Rapid prototyping is a versatile technology capable of handling even the most complex medical devices. From intricate surgical instruments to diagnostic imaging tools, rapid prototyping supports diverse applications.

How It Works for Complex Devices:

- Multi-Material Prototypes: Advanced 3D printing allows the combination of materials with different properties, such as flexible polymers and rigid metals, in a single prototype.

- Functional Prototypes: These are more than just visual models. They can include embedded sensors, actuators, and working electronics for performance testing.

- Wearables and Implants: Technologies like SLA (stereolithography) and DMLS (direct metal laser sintering) enable the creation of biocompatible prototypes for devices like orthopedic implants or smart wearables.

Example: A MedTech startup developing a robotic surgical arm used rapid prototyping to refine the mechanics, ergonomics, and software integration simultaneously, drastically reducing development time.

Myth #2: “It’s Just About Speed”

The Reality:

While speed is a significant advantage of rapid prototyping, its benefits extend far beyond faster production timelines.

Key Advantages Beyond Speed:

- Enhanced Iteration: By producing prototypes quickly, teams can test, receive feedback, and refine designs multiple times before finalizing.

- Cost Efficiency: Early-stage prototypes help identify design flaws, avoiding costly changes during manufacturing.

- Collaborative Design: Prototypes provide a tangible model for cross-functional teams to review, facilitating better communication and alignment.

How It Adds Value:

Rapid prototyping fosters a fail-fast, learn-fast approach, allowing designers to test hypotheses and integrate user feedback at every stage. This iterative cycle enhances overall product quality and user satisfaction.

Myth #3: “It Doesn’t Help with Regulatory Approval”

The Reality:

Prototypes play a critical role in meeting regulatory requirements. They allow MedTech companies to validate design intent and functionality, ensuring compliance with stringent standards like those set by the FDA or ISO.

How Prototypes Support Regulatory Success:

- Early Testing: Prototypes enable testing of safety, usability, and performance before clinical trials, addressing issues proactively.

- Documentation: Validation data from prototypes contributes to required documentation, such as Design History Files (DHF).

- Risk Management: Early prototyping highlights potential risks, which can be mitigated and documented in the Risk Management File as per ISO 14971.

Example: A company developing a wearable ECG monitor used functional prototypes to refine software algorithms and improve electrode placement. These adjustments, validated through usability testing, facilitated a smoother FDA 510(k) submission.

Myth #4: “It’s Only Useful for Pre-Production Stages”

The Reality:

Rapid prototyping is valuable across all phases of hardware product development, from ideation to post-launch improvements.

Applications Beyond Pre-Production:

- Pilot Production: Create low-volume runs of devices for clinical trials or limited market releases.

- Post-Market Modifications: Quickly iterate and refine designs based on real-world feedback without disrupting full-scale manufacturing.

- Marketing and Training Tools: Produce realistic models for sales demonstrations or clinician training.

Example: A MedTech company used rapid prototyping to create training simulators for a new surgical device, enabling surgeons to familiarize themselves with the tool before it hit the market.

Myth #5: “It’s Too Expensive for Startups”

The Reality:

Rapid prototyping can be a cost-effective solution, especially for resource-constrained startups.

Why It’s Affordable:

- Reduces Waste: Identifying and fixing design flaws early prevents expensive tooling changes later in production.

- Pay-As-You-Go: Many rapid prototyping services allow companies to create parts on demand without investing in equipment.

- Outsourcing Options: Partnering with prototyping firms eliminates the need for in-house infrastructure.

How Startups Benefit:

Startups can leverage rapid prototyping to gain a competitive edge by shortening development cycles, minimizing risk, and demonstrating proof of concept to investors.

Myth #6: “Prototypes Are Not Realistic”

The Reality:

Modern prototyping technologies produce highly realistic and functional models, closely mimicking final products.

Technologies That Enable Realism:

- High-Resolution 3D Printing: Achieves detailed surfaces and precise geometries.

- Multi-Material Printing: Combines materials with different properties, such as flexibility or conductivity.

- Advanced Finishing Techniques: Post-processing methods like polishing and painting make prototypes indistinguishable from production units.

Example: A company developing a handheld diagnostic tool used a prototype with fully functional electronics to test user interaction, proving its readiness for market launch.

Steps to Effectively Leverage Rapid Prototyping for Your Device

- Design for Manufacturability

While you may be focusing on speed, make sure your design is scalable and ready for mass production. Keeping manufacturing in mind will ensure your prototypes are aligned with production goals. - Use Prototypes for Testing

Testing is crucial. Utilize rapid prototyping to create multiple versions of your device and conduct real-world tests. The data from these tests will be invaluable when seeking FDA approval. - Collaborate with Regulatory Experts

Having a regulatory expert on your team ensures that your prototypes meet all necessary guidelines for approval. Their insights will streamline the process and reduce setbacks.

A Look Ahead: Rapid Prototyping Trends to Watch in 2025

As the industry moves into 2025, rapid prototyping technologies are advancing rapidly. New 3D printing methods, better material options, and improved digital design tools are emerging, enabling faster, more accurate prototypes. Keep an eye on these trends to stay ahead of the competition.

Conclusion: Making Your 2025 MedTech Goals a Reality

As we enter the new year, it’s the perfect time to leverage rapid prototyping to transform your medtech development. This tool can fast-track FDA approvals, reduce time to market, and improve your product’s quality. By integrating rapid prototyping into your workflow, you can set your startup up for a successful 2025 and beyond.

Let’s make this year the one where your MedTech innovation becomes a reality. Get in touch with OVA Solutions today to learn how we can help you use rapid prototyping to make your development process faster, smoother, and more compliant.

For a deeper dive into medical device engineering and its role in commercialization, check out this comprehensive guide on optical medical device development. It explores practical strategies to bring innovative devices to market effectively.