Table of Contents

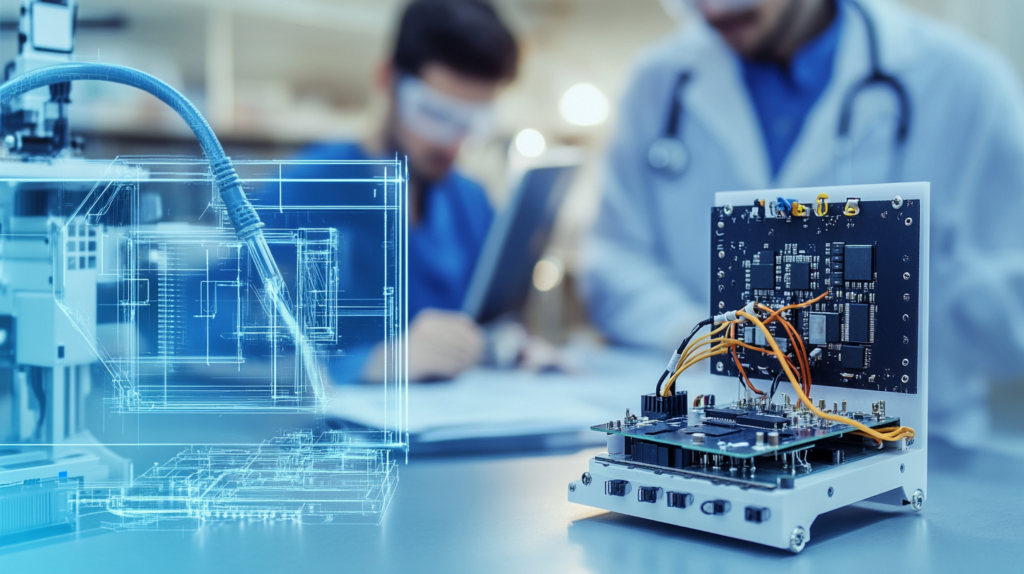

The hidden nightmare in engineering product development?

Trying to scale or re-certify a device built in China — and realizing you have zero access to the source files.

No editable CAD. No firmware loaders. No test protocols. Just a box that works… until it doesn’t.

At OVA Solutions, we’ve rebuilt hardware for MedTech clients caught in this exact situation. What starts as a cost-saving OEM deal becomes a six-figure scramble to reverse-engineer your own IP.

Here’s what you need to know — before it happens to you.

Why Source Files Aren’t a Detail — They’re the Foundation

In medical and wellness device development, engineering isn’t just about performance. It’s about documentation, traceability, and transferability.

If your team can’t edit or validate what you’ve built, you don’t control the product — and you certainly can’t scale or pass regulatory audits.

This is why engineering product development isn’t complete without full file access. Because when those files vanish, so does your ability to move fast, change suppliers, or fix issues.

5 Challenges of Rebuilding Without Source Files

Here’s what experienced engineers know happens when you’re forced to reverse-engineer a black-box device from China:

🧠 Engineering Product Development: 5 Challenges of Rebuilding Chinese Hardware Without Source Files

| Challenge | What Most Teams Think | What Actually Happens | Bold, Actionable Advice |

|---|---|---|---|

| 1. No Access to Editable CAD or Tooling Files | “We have the 3D model screenshots, that’s enough.” | PDF drawings and STEP files don’t include tolerances, assembly logic, or mold-specific features. You can’t manufacture or modify without native CAD. | Reverse-engineer critical parts via 3D scanning, CT scans, or manual metrology. Rebuild in parametric CAD with constraints. Mark as v2 and validate compatibility. |

| 2. Missing PCB Design Files and Firmware Loaders | “We can read the board layout and firmware from the device.” | You may recover binaries or traces, but without schematics, BOM, and source code, debugging, updates, and re-certification are blocked. | Use decapping or X-ray to reverse PCB layers. Trace connections manually or with tools. Rebuild BOM based on markings and behavior. Don’t recompile — redesign. |

| 3. Undocumented Part Substitutions and Localized Specs | “We’ll use the same components.” | Many parts are non-exported variants or lack global equivalents. Specs may differ slightly — enough to create failures under stress, EMI, or heat. | Create a validated alternative BOM (AltBOM). Run electrical, thermal, and EMC tests on all substitutes. Involve global distributors early for cross-referencing. |

| 4. Obscure Assembly and Test Processes | “The device works, so we’ll just disassemble it and rebuild.” | Glue types, soldering profiles, fixture tolerances, and operator heuristics are often undocumented. Result: poor yield or inconsistent QA. | Build an experimental teardown lab. Document every operation under microscope. Define new SOPs with DFM/DFA principles and track first-pass yield from pilot builds. |

| 5. Loss of Regulatory Traceability | “We’ll just replicate the unit for CE/FDA.” | Without original verification protocols, reports, and traceability logs, you’re non-compliant. Even if the hardware works, you can’t prove it does. | Reconstruct full Design History File (DHF) and Device Master Record (DMR). Mark rebuilt areas clearly. Document rationale, revalidation plans, and gaps for auditors. |

Why This Happens More Than You Think

OEMs in China often build without ever releasing core files. Sometimes it’s deliberate. Sometimes it’s cultural. But in engineering product development, the result is the same:

- Your team can’t modify designs

- You’re locked to one manufacturer

- You can’t localize or re-certify easily

- You lose months trying to reverse-engineer basic specs

The product may look finished — but the foundation is hollow.

How OVA Prevents These Failures from Day One

At OVA Solutions, we approach engineering product development with future flexibility built in:

- Native CAD files, versioned from v0.1 onward

- Full BOM and layout traceability

- Firmware loaders and commented source code

- Validation and test protocols aligned with CE/FDA expectations

Our engineers think like regulators and scale-up teams — not just prototypers.

So when you need to move factories, raise funding, or pass an audit, your documentation supports you — not stops you.

A Founder’s Nightmare: “We Couldn’t Touch It”

One client came to us with a high-functioning diagnostic device — fully built in China, working perfectly… until they wanted to tweak it. In their engineering product development

They had:

- No editable CAD

- No access to the bootloader

- No manufacturing documentation

Their CE submission stalled. Their investor delayed funding. Their only option was full reengineering.

We helped them rebuild — but it took 4 months and over \$200K.

That’s the real cost of ignoring documentation in engineering product development.

6 Questions Every MedTech Team Should Ask

✅ Do we have editable CAD and Gerber files in-house?

✅ Is our firmware fully under version control — including loaders?

✅ Can we pass a regulatory audit without vendor intervention?

✅ Could we rebuild this product elsewhere with current documentation?

✅ Do we own the BOM and know the sourcing strategy?

✅ Have we simulated a tech transfer using only what we own?

If you’re unsure — your engineering product development foundation is incomplete.

What OVA Clients Get Instead

We help MedTech companies avoid reengineering hell by:

- Building open, portable, documented design systems

- Structuring BOMs and DHFs for audit and transfer

- Ensuring hardware and firmware align with future updates

- Delivering real control — not just working prototypes of engineering product development

With OVA, engineering product development is built to scale, survive scrutiny, and shift vendors without friction.

Don’t Let Your Hardware Become a Black Box

If you’re building in China — or trying to recover from it — let’s talk.

At OVA Solutions, we design engineering systems you can own, modify, and scale — without begging for your own files.

📅 Book a call with our CEO: https://calendly.com/lisa-voronkova/30min