Table of Contents

The harshest truths in mechanical design services?

You often don’t find them in CAD — you find them buried inside a glued, press-fit, undocumented device shipped from China.

At OVA Solutions, we’ve been called into MedTech projects where teams had no choice but to reverse-engineer a finished product: no source files, no access to firmware, no tooling data. Just a product they needed to replicate or re-certify.

The engineering effort that follows isn’t simple replication. It’s reconstruction. And it’s filled with traps.

Here’s what we’ve learned the hard way — so you don’t have to.

Why Reverse Engineering Isn’t a Shortcut — It’s a Parallel Process

In high-stakes hardware development, assumptions are expensive. Teams often believe that disassembling and scanning a product will reveal the design.

It doesn’t.

In mechanical design services, true design intent includes:

- Tolerance schemes

- Assembly logic

- Moldability constraints

- Regulatory-driven decisions

Reverse engineering only gives you shape. It doesn’t give you reasoning.

That’s why what looks fast on paper often becomes a six-month detour.

4 Hard Lessons from Reverse Engineering Chinese Devices

If you’re working in MedTech and considering rebuilding hardware made overseas, read this before you start:

🧠 Mechanical Design Services: 4 Hard Lessons from Reverse Engineering Products Made in China

| Lesson | What Most Teams Assume | What Actually Happens | Bold, Actionable Advice |

|---|---|---|---|

| 1. “We Can Just Scan the Enclosure” | “A 3D scan will give us everything we need to recreate the casing.” | Scans miss internal mounting logic, material constraints, wall thickness tolerances, and draft angles critical for molding. | Use scan data only as a starting point. Rebuild models in parametric CAD with DFM constraints. Validate by prototyping and fit testing. |

| 2. “We’ll Extract Mechanical Tolerances from the Assembled Unit” | “We can measure and reproduce every part manually.” | Wear, adhesives, press-fits, and design-for-assembly choices are often invisible once built. Tolerances may reflect assembly compensation — not intent. | Disassemble multiple units. Identify design intent vs. physical compensation. Recreate GD\&T schemes with fresh tolerance stacks. |

| 3. “The BOM is Easy to Rebuild” | “We’ll find part numbers on components and source them again.” | Many components are custom, relabeled, obsolete, or China-only. Substitutions often change thermal, mechanical, or EMC behavior. | Use reverse BOM tools plus expert validation. Build an AltBOM with at least two global sources per item. Run mechanical & environmental validation on all alternates. |

| 4. “This Will Save Us Time Compared to Redesigning” | “Rebuilding is faster than designing from scratch.” | Reverse engineering often takes longer due to undocumented exceptions, translation issues, and iterative errors. You’re not saving time — just changing where you spend it. | Scope reverse engineering as new development. Budget 2–3× more time for verification. Reuse only what’s validated, not what’s “visible.” |

The Hidden Risks Behind “Let’s Just Rebuild It”

MedTech teams often find themselves here after:

- OEMs refuse to share files

- A contract manufacturer goes silent

- A prototype was built abroad with no traceability

And suddenly, your only option is reverse-engineering your own IP.

If your mechanical design services don’t include structured teardown methodology, GD\&T expertise, or supplier matching — you’re heading into a black box with a flashlight.

What OVA Does Differently

At OVA Solutions, we don’t treat reverse engineering as a workaround. We treat it as a controlled development pipeline.

Our approach to mechanical design services includes:

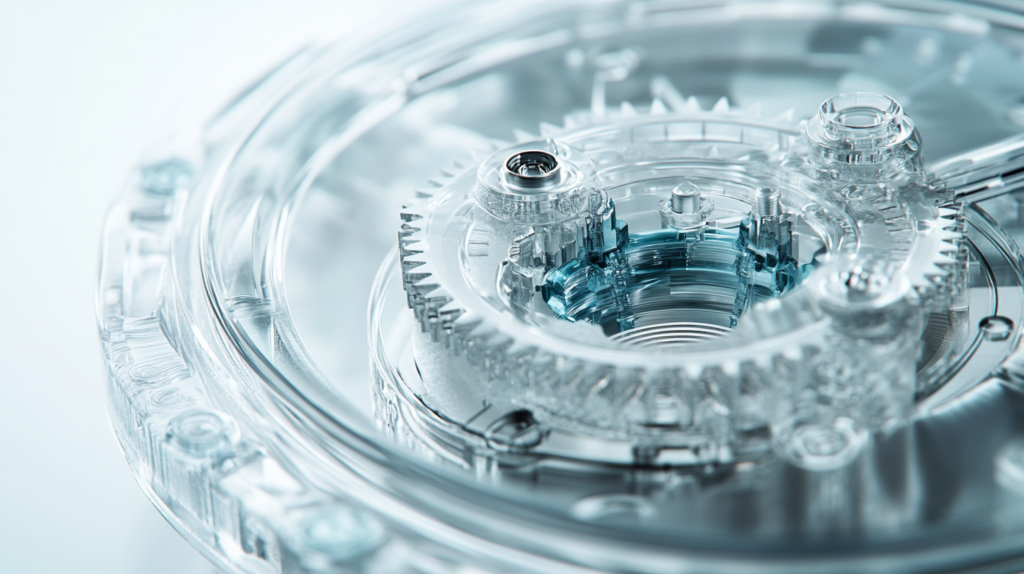

- Lab-grade teardown workflows and 3D scanning

- Re-CAD with parametric constraints, DFM logic, and tolerance mapping

- Engineering change logs and version control even during reconstruction

- Integration with QA and regulatory teams for compliant revalidation

We don’t just replicate geometry. We restore design authority. In mechanical design services

Why This Matters for MedTech Investors and Operators

Reverse-engineering affects:

- Time to market

- Audit readiness

- Supplier transition strategies

- Perceived IP risk

And in a regulated space, poor reconstruction leads to rejected submissions, expensive recalls, and lost investor confidence.

Mechanical design services must not only recover geometry — they must rebuild trust.

5 Questions Every Hardware Team Should Ask Before Rebuilding

✅ Do we know the original DFM and material constraints?

✅ Are our CAD models parametric and tolerance-based — or just surface-level?

✅ Have we verified BOM parts for global availability and equivalence?

✅ Are we revalidating assumptions — or copying errors?

✅ Is our reverse engineering documented, versioned, and auditor-ready?

If not — your mechanical design services may be replicating the product, but not recovering the system.

What OVA Clients Get When They Rebuild

We help MedTech teams turn a black-box product into:

- A clean, compliant engineering asset

- A documented CAD and BOM stack

- A transfer-ready DMR/DHF

- A product you can own, modify, and scale

Because reverse engineering should never mean starting over blind.

With OVA, mechanical design services become an asset — not a salvage operation.

Ready to Regain Control of a Black-Box Device?

We’ve helped MedTech founders and OEM teams rebuild lost designs — and rebuild confidence with investors, regulators, and manufacturing partners.

Let’s talk.

📅 Book a call with our CEO: https://calendly.com/lisa-voronkova/30min