In the highly regulated and fast-paced world of medical device development, ensuring continuous improvement and learning from past experiences is essential to the success of any project. One of the most effective tools for achieving this is retrospective meetings. These meetings, often held at the end of a project phase or milestone, allow teams to reflect on their processes, identify areas for improvement, and develop actionable strategies to enhance future outcomes.

Retrospective meetings are a cornerstone of agile methodologies, but their principles can be adapted to any framework within the medical device industry. This article explores how retrospective meetings can drive better decision-making, improve processes, and lead to enhanced medical device outcomes.

Table of Contents

What are Retrospective Meetings?

A retrospective meeting is a structured meeting that allows project teams to reflect on the work they have done, evaluate what went well, identify challenges, and agree on improvements for future work. This process is common in agile environments, particularly in software development and product management, but it can be effectively applied to the medical device industry to drive continuous improvement in development and manufacturing processes.

The main goal of a retrospective is to create a safe and open environment where team members can discuss their experiences candidly. The outcomes of a retrospective meeting typically lead to better collaboration, refined processes, and more effective decision-making.

Key Elements of Retrospective Meetings:

- What went well: Identifying successes and positive aspects of the project or process.

- What didn’t go well: Discussing obstacles or areas where the team faced challenges.

- Action items for improvement: Developing specific strategies or changes that can enhance future work.

- Team collaboration: Creating a space for team members to communicate openly and improve how they work together.

The Importance of Retrospective Meetings in Medical Device Development

In the medical device industry, the stakes are high. Regulatory requirements, patient safety, and product efficacy are non-negotiable, and any missteps can have severe consequences. Retrospective meetings offer a structured way to reflect on the team’s performance and ensure that processes are continuously evolving in a positive direction. These meetings help identify inefficiencies, improve collaboration, and ultimately lead to better products and more efficient development cycles.

Here are some key reasons why retrospective meetings are vital in the context of medical device development:

1. Improving Cross-Functional Collaboration

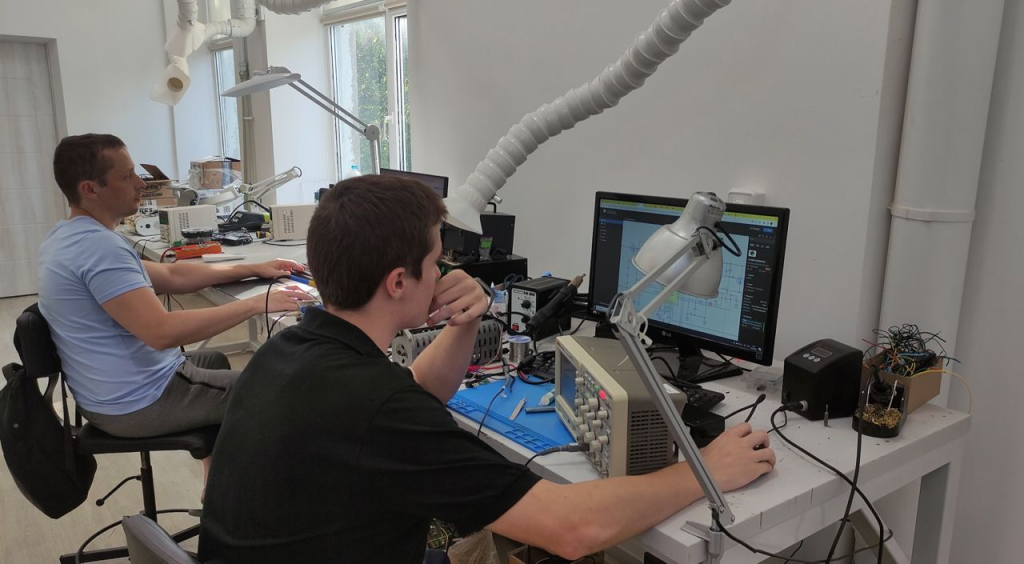

Medical device development often involves collaboration across multiple departments: design, engineering, regulatory affairs, quality control, marketing, and manufacturing. Retrospective meetings create an opportunity for teams to openly discuss how well these departments are working together.

Actionable Tips:

- Use retrospectives to identify communication gaps between departments.

- Create action items to enhance collaboration, such as improving meeting schedules, using collaborative project management tools, or aligning on goals and expectations earlier in the process.

2. Ensuring Regulatory Compliance

Regulatory standards are integral to medical device development. However, understanding and adhering to these standards can be complex, with multiple stages of testing, documentation, and approval. Retrospective meetings allow teams to evaluate how well the regulatory process is being followed, identify compliance challenges, and address any delays or misunderstandings in meeting regulatory deadlines.

Actionable Tips:

- Use retrospectives to identify regulatory pain points and streamline documentation or submission processes.

- Reflect on any compliance issues that may have delayed product development or approval and create strategies for avoiding them in future projects.

3. Enhancing Product Quality and Performance

Quality assurance is a core aspect of medical device development, as products must meet stringent safety, performance, and efficacy standards. Retrospective meetings provide an opportunity to analyze the outcomes of quality control measures, identify issues in product testing, and refine protocols to improve the final product.

Actionable Tips:

- Evaluate the results of testing and validation during retrospectives to understand how design flaws or manufacturing defects can be prevented in the future.

- Discuss ways to integrate continuous quality assurance practices throughout the development cycle.

4. Reducing Risks and Preventing Mistakes

Risk management is a critical component of medical device manufacturing. Retrospective meetings help identify risks that were encountered during a project phase and discuss what could have been done differently. These meetings also help develop strategies to mitigate risks in future projects, reducing the likelihood of mistakes that could compromise the safety or efficacy of a product.

Actionable Tips:

- Review potential risks that were either mitigated or not fully addressed during the project.

- Implement a risk registry to track issues discussed in retrospectives and ensure that they are addressed in subsequent stages of development.

5. Streamlining Processes for Future Development Cycles

Efficient processes are key to meeting development deadlines and staying within budget. Retrospective meetings allow teams to review workflows, identify bottlenecks, and optimize processes for future projects. By continuously refining internal processes, teams can deliver high-quality medical devices more quickly and cost-effectively.

Actionable Tips:

- Reflect on development timelines and identify ways to accelerate certain processes, such as prototyping, testing, or regulatory submission.

- Explore opportunities for implementing lean practices to reduce waste and improve efficiency.

6. Fostering a Culture of Continuous Improvement

A culture of continuous improvement is essential for long-term success in the medical device industry. Retrospective meetings help to create this culture by encouraging teams to be reflective, transparent, and proactive in identifying areas for improvement.

Actionable Tips:

- Encourage team members to bring up any challenges or obstacles they faced during the project and collaboratively brainstorm solutions.

- Implement regular retrospectives at key project milestones to maintain a focus on ongoing improvement.

Best Practices for Conducting Effective Retrospective Meetings

While retrospective meetings can be highly beneficial, their success depends on how well they are conducted. Here are some best practices to ensure that your retrospective meetings deliver meaningful outcomes and drive improvements in your medical device processes.

1. Set Clear Objectives and Agendas

Each retrospective meeting should have a clear focus and set goals. Whether it’s reviewing a specific project phase or identifying overall process improvements, having an agenda ensures that the meeting is productive and time-efficient.

Tip:

Start each retrospective by setting clear expectations about what will be discussed and what the team hopes to achieve during the session. This keeps the meeting focused and ensures that all relevant topics are addressed.

2. Foster a Safe and Open Environment

For a retrospective meeting to be successful, team members must feel comfortable sharing their thoughts and opinions. A safe environment where everyone can voice their concerns and offer constructive feedback is essential for identifying areas for improvement.

Tip:

Establish ground rules that promote openness, such as encouraging respectful listening, ensuring everyone has a chance to speak, and focusing on solutions rather than blame.

3. Use Data and Metrics to Drive Discussions

Data and performance metrics are invaluable when assessing how well processes are functioning. By presenting data on key performance indicators (KPIs) such as timelines, budget adherence, or product testing outcomes, the team can focus discussions on concrete issues and measurable results.

Tip:

Use visual tools like dashboards, charts, or graphs to present data in a way that makes it easy for the team to identify trends and areas for improvement.

4. Actionable Takeaways

A retrospective meeting should not just be about identifying issues—it should also result in actionable solutions. Create specific, measurable action items that the team can implement in future development cycles to improve processes and outcomes.

Tip:

End each retrospective by assigning action items to team members and setting deadlines for follow-up. This ensures that the feedback gathered is translated into meaningful improvements.

5. Follow Up and Track Progress

To maintain momentum and ensure that the outcomes of the retrospective meetings are implemented, follow-up meetings or check-ins should be scheduled. This allows the team to track the progress of action items and ensures that improvements are being realized.

Tip:

Track action items in a shared project management tool and regularly review progress to hold the team accountable and ensure continued improvement.

Conclusion

Retrospective meetings are an invaluable tool for enhancing the medical device development process. By providing a structured space for teams to reflect on their work, identify challenges, and implement solutions, retrospectives foster a culture of continuous improvement. In the highly regulated and complex field of medical device manufacturing, these meetings help ensure that products are not only compliant with industry standards but also meet the highest levels of quality, safety, and efficacy.

By focusing on improving collaboration, refining processes, and addressing risks proactively, retrospective meetings can help teams in the medical device industry create more effective devices, streamline development cycles, and improve overall outcomes. As the medical device landscape continues to evolve, leveraging the insights gained from retrospective meetings will be essential for staying competitive and driving innovation in patient care.

How have retrospective meetings improved your team’s performance and product development process? What specific improvements have you implemented based on feedback from retrospectives?

430 Park Ave, New York, NY 10022, USA

430 Park Ave, New York, NY 10022, USA Paevalille tn 6, Office 84, Estonia, Tallinn, 13517

Paevalille tn 6, Office 84, Estonia, Tallinn, 13517 Barykadna St 7, Dnipro, Ukraine, 49000

Barykadna St 7, Dnipro, Ukraine, 49000